LUX has three battery banks: the 600AH house bank, a starboard starting battery, and a port starting battery. The original electrical system uses an automotive solenoid (a relay) to connect the house bank to the starting battery of whichever of the engines is running (or both, when both engines are running). The charging system relies on the alternator internal voltage regulator to prevent overcharging the batteries. The alternator internal regulator is not a smart three-stage regulator (bulk, accept, float); it simply limits the output voltage to the peak battery voltage of lead-acid or AGM cells, about 14.6v on LUX. The alternator output goes directly to the starting battery, which is connected to the house bank when the alternator is running. On the Leopard 40 Owner's Manual schematic, the R output of the alternator energizes the solenoid coil, causing the solenoid to close whenever the alternator is running. Not shown on the schematic is a suppression diode across the coil connections, used to absorb the reverse voltage spike that results when the energizing current stops.

LUX has three battery banks: the 600AH house bank, a starboard starting battery, and a port starting battery. The original electrical system uses an automotive solenoid (a relay) to connect the house bank to the starting battery of whichever of the engines is running (or both, when both engines are running). The charging system relies on the alternator internal voltage regulator to prevent overcharging the batteries. The alternator internal regulator is not a smart three-stage regulator (bulk, accept, float); it simply limits the output voltage to the peak battery voltage of lead-acid or AGM cells, about 14.6v on LUX. The alternator output goes directly to the starting battery, which is connected to the house bank when the alternator is running. On the Leopard 40 Owner's Manual schematic, the R output of the alternator energizes the solenoid coil, causing the solenoid to close whenever the alternator is running. Not shown on the schematic is a suppression diode across the coil connections, used to absorb the reverse voltage spike that results when the energizing current stops.

When both engines are running, the respective solenoids are activated and all three batteries are charged from both alternators. The internal regulators on the alternators rarely have exactly the same output voltage, causing unbalanced charging current as the batteries reach full charge. In a discharged state, the battery voltage is low enough that both alternators will typically charge at near their rated capacity. But as the batteries become charged, the voltage approaches that of the regulator. When this happens, one alternator will be providing more current than the other. On LUX, it was normal to see 60A on both alternators when the house bank needed charging, and 20A on one alternator and 5A on the other once the batteries were fully charged.

One of our solenoids died and we were faced with replacing it. We could replace it with another solenoid or we could use something smarter (better?). I was not very happy with the existing solenoid system. It connected the starting battery to a discharged house bank, causing a current surge as the starting battery and alternator attempt to charge the house bank back to a fully charged state. This causes stress on the starting battery as well as on the solenoid contacts. If the house bank is discharged 50% (12.2v) and the starting battery is fully charged (12.6v), the resulting current surge can be quite large. While starting batteries are built to provide large currents for short periods, they are not built for deep discharge, which is basically what is happening. It might take several hours for the charging system to bring the combined battery bank back up to 12.6v.

If engine maintenance is being conducted that prevents charging the starting battery, it may wind up with insufficient power to start the engine. In this case, it would be sufficient to start the other engine, then use a jumper wire to activate the solenoid on the dead starting battery in order to charge it from the running engine. It would take a while for it to charge because the house bank will need to be brought back up to a high enough state of charge to start the dead engine.

In another scenario, it is possible for the ACR to cycle. Blue Sea Systems has a good explanation in their article Preventing Cycling in Battery Combiners.

The above scenarios tell me that the design could be improved. The ultimate installation would be a 3-stage charge controller on each engine. Balmar and Ample Power both provide systems that would work well, at a cost that's $1000 or more. The Balmar will need two of Max Charge controllers, a Center Fielder to control both chargers, and two Duo Charge units to provide charging of the starting batteries. The alternators will probably need to be modified to provide the connections for the charge controllers to control the field voltage, which is how they regulate the output.

An alternative is to replace the solenoid with a Blue Sea Systems Automatic Charging Relay (ACR), also known as a battery combiner. In this system, the ACR functions similarly to the solenoid. However, it is smart enough to connect the starting and house bank only when the voltage of either is above the trigger voltage for some amount of time. For the ACR, it is 13.0v for 90 seconds on either battery, see ACR Explained.

I decided that the best way to reconfigure the system was for the alternator on each engine to charge the house bank first and have the ACR connect the starting battery when the house bank reached the ACR threshold. In this scenario, a discharged house bank gets full alternator output until it reaches 13.0v for 90 seconds. The ACR will then close, connecting the starting battery to the house bank. The battery voltages are closer to each other and a relatively small amount of current will cause the starting battery to quickly reach 13.0v. This has less effect on both batteries and avoids the cycling problem referenced above.

I decided that the best way to reconfigure the system was for the alternator on each engine to charge the house bank first and have the ACR connect the starting battery when the house bank reached the ACR threshold. In this scenario, a discharged house bank gets full alternator output until it reaches 13.0v for 90 seconds. The ACR will then close, connecting the starting battery to the house bank. The battery voltages are closer to each other and a relatively small amount of current will cause the starting battery to quickly reach 13.0v. This has less effect on both batteries and avoids the cycling problem referenced above.

Another benefit of this configuration is that either engine will charge the house bank. When the house bank reaches the ACR's 13.0v threshold for 90 seconds, both starting batteries will be connected and a single engine can charge all three batteries.

NOTE: Adjacent to the ACR is the shunt that is used to sense alternator output current and is shown on one of the meters at the helm.

The small gray electrical box next to the solenoid/ACR contains the relay that controls power to the engine compartment fan. Since the alternator R output is no longer used, the relay must be connected to the engine ignition circuit. This means that the engine compartment fan runs when the ignition switch is turned on. With the old system, the relay that drives the fan wouldn't be activated until the alternator's R output energized the relay.

WARNING: One of the fuses and holders in this box was melted, which I replaced with a similar fuse holder. It uses automotive style spade fuses. It was not clear what caused the fuse and holder to get hot enough to melt but not blow the fuse. It is advisable to periodically check these fuse holders. Also, the box is old enough that the edges of the cover broke off. I replaced the screws with 2.5-inch screws that screw into the backing plate.

What about the Victron charger? I connected its main output to the house bank. It has a second output, which is limited to 4A for charging a starting battery, but we have two starting batteries. With the main output connected to the house bank, it functions just like the engine alternators, charging the house bank first, then adding the starting batteries when 13.0v is reached.

Update 5 Jan 14:

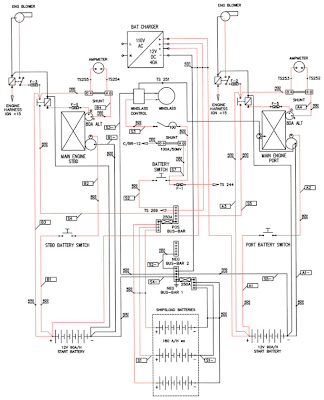

I've been asked for a schematic of the change. I was able to use the L40 owner's manual schematic to show something of the wiring change. The left picture is a close-up of the upper left part of the complete engine/battery schematic before the modification. I've identified the solenoid and the fan relay. Disconnect the wires from the old solenoid, noting the wire numbers. I've found that the numbers match what's on the schematic. If your boat doesn't have labels on the wires, then mark them yourself with tape and a marker. Mount the ACR. Connect the House bank wire and the alternator output to one lug. Connect the Starting battery wire and the F-3 (fuse for Eng Blower) wire to the other lug. It doesn't matter which lug, because the ACR senses on both lugs and will close when either of them is 13.0v or greater for 90 seconds. You can disconnect the wire from the F-5 fuse since it is not needed for the ACR. You can wrap the F-5 wire connector in tape and heat shrink and wire-tie it back on itself. You could remove the wire from the system if you have the inclination and time. It travels in one of the black covers, which is why I decided to simply cover it and protect it from shorting. F-3 is found in the gray box and I think that F-5 is also located there - trace the wiring to make sure. Make sure that the Eng Blower fan relay still has a ground, which was connected to one side of the solenoid's coil. In the second photo that shows the ACR with connections, there are two big wires and one small red wire on the left lug. There is one big wire on the right lug. The left lug is connected to the alternator output and to the house bank and to F-3. The right lug is connected to the starting battery.

Summarizing, you're going to swap the locations of the Starting and House wires where they connect to the ACR and you're going to not use the wire from F-5. The schematics below are before the modification.

-Terry

8 comments:

Terry, excellent write-up on charging system for cats. Do you have a schematic of the final configuration you can share?

Thanks,

Steve

S/V Panasea, L43

I added the L40 engine and battery schematics and a description of the modification. Let me know if it isn't clear.

-Terry

Terry, very interested in this upgrade as we are having nothing but trouble keeping the house charged. Extremely frugal in our use, seems like the starting batteries get full whack, the house nothing but crumbs.

Maybe a silly question, did you bypass the other solenoid or simply replace one with the ACR unit, leaving the other alone. Looking for some install help, currently in nanny Cay Tortola.

Cheers

Peter,

Both solenoids are now replaced with ACRs. Initially, I only replaced one solenoid, because it had died. When I had the opportunity, I changed the other solenoid for another ACR.

If you don't have a battery monitor, that's the first thing you need. With it, you can determine the actual capacity of the house bank, what loads are running, and how much they draw.

Say Hi to Lance at VSV for me, if you run into him.

-Terry

Peter,

Also make sure to read this post, which includes the battery monitor installation:

Victron Multi 3000 12vDC 120vAC 50A Setup

If you have an old Sentry charger, check out this one:

Getting Juiced at the Dock

and

Sentry Charger Settings

If you have a Sentry charger, you should consider replacing it. Ours failed to charge , which prompted me to find the bad capacitor. We eventually replaced it and have enjoyed the Victron.

-Terry

Terry, this is a great write-up and very helpful as I'm following your lead on this.

One point that is slightly confusing though. Why did you choose to not continue to use the R terminal on the alternator to control the engine room fan? I assume the R terminal is still energized when the engine is running.

Second question is: where did you find ignition power in the engine room? I'm sure if I poke around I'll find it somewhere but it sounds like you already found a good ignition source.

-Rick

Rick,

One of the old alternators died and we didn't have an R output on the replacement alternator.

The alternate source of ignition was in the gray box that contains the fuses and relays. It comes on when the ignition switch is turned on. I've found that different boats have slightly different configurations of ignitions. LUX has a toggle switch for ignition and a momentary pushbutton for starting.

-Terry

That makes sense. When I looked at your wiring diagrams vs. the diagram I have for our L43 we have both an R and an L terminal on our alternator where your manual only shows an R. Our instrument panel has a traditional key for starting and a button for killing the engine.

I will probably use the switched power in the gray box to turn the blower on as well. It's way easier to check that it's working if it comes on with the key/ignition vs after the engine has started.

Thanks again for all your blog postings, they are incredibly helpful.

-Rick

Post a Comment