|

| Damaged Engine Mount (Rubber bushing) |

In late 2015, we were on LUX, heading down the ICW to south Georgia where we were leaving LUX for a few months. We had just made it into South Carolina and Gee reported a new grinding type sound from the port engine (behind her bunk) when under way. Sure enough, it was distinctly different than the sound from the port engine. We had made it to Georgetown, SC by this time. We lucked out - a diver was working on zincs on another boat on the dock, so we were able to get him to check out the saildrives. He reported that the port drive was loose. A little investigation in the engine compartment with a light showed the engine mount on the saildrive seemed to be heavily worn and should be replaced. (See Damaged Engine Mount)

We called around and found one that could be shipped to Charleston, SC, where we planned to replace it. We motored the rest of the way to Charleston using the starboard engine except for docking. Of course, shipping parts to any port is fraught with risk and this was no different. It took all of the first day in Charleston to get the part and make it back to LUX.

Next, we started looking at removing the existing engine mount. Imagine our surprise upon looking closer and finding a crack in the flywheel housing. A closer examination showed that the crack was all the way around the perimeter of the saidrive’s connection to the flywheel housing.

|

| Cracked Housing - Outboard |

Our reaction was a bit stronger than “Oh No!” Our immediate thought was that it was going to require professional help and cost several thousand dollars to fix. Time to break out the phone and start making calls. The soonest we could be helped was the following week. Not only would it cost a bunch to make the repair, we’d be stuck in Charleston at an expensive marina. It was time to go to dinner and think about the situation.

Think, think, think

How did it happen? The last charter in the BVIs was a disaster. LUX drug anchor and ran aground. Damage was fairly minimal, but the port prop took a few hits and had to be straightened. We think that a crack started then and four years of working back and forth extended it around the saildrive.

|

| Cracked Housing - Inboard |

|

| It's Cracked All the Way Around! |

Our port engine wasn’t totally out of commission. It could be used for docking as long as we didn’t need much power. We had made it from Georgetown to Charleston on one engine. Waiting in Charleston for repairs didn’t seem useful. There were other service companies in Georgia. So we decided to continue south, primarily on one engine.

As we made our way south, we thought about the problem, looked the engine over, and studied the parts diagrams. We could just slide the engine back about four inches and replace the cracked housing. Hmmm. Really? We had many hours to think on it. Checking eBay, we found a used flywheel housing that was much less than a new housing. We ordered it with shipment to our destination marina in Georgia.

We thought about how to support the engine so we could decouple it from the saildrive and replace the flywheel housing. We started collecting parts we thought would be of use. The end result was that we decided that we could to the job.

Doing the Job

|

| Supporting the Engine |

Mike orchestrated the repair, using an oak board, lines, and turning blocks to support the engine. It took most of the day to replace the housing. The old housing was indeed cracked all the way around the saildrive mount.

The new housing arrived in great shape and was soon installed and the engine coupled back to the saildrive.

|

| Broken Flywheel Housing |

|

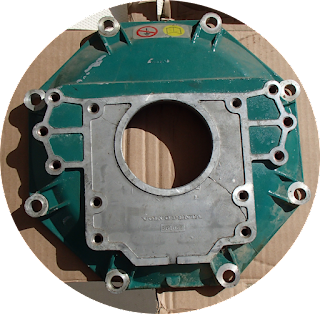

| New Flywheel Housing |

The saildrive engine mount still had to be replaced. Just getting the old engine mount bushing out was a problem. It wouldn’t move. We had rented a car so we headed off to Tractor Supply, the source for all sorts of big parts. We returned with a 2-1/8 inch socket, a big wheel puller, all-thread rod, big washers, and a few other parts.

These parts did the job, allowing us to pull the old bushing and install the new bushing. We had to use heat on the saildrive mount to get the old bushing out and the new busing in (note the heatgun in the photo of installing the new bushing).

We were back to two fully functioning engines without having to spend too much time or money.